Difference between revisions of "Truck transport"

Bendikhansen (talk | contribs) |

Bendikhansen (talk | contribs) m (Text replacement - "category:Measures" to "category:Solutions") |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | [[file:icon_upstream.png|right|150px|link=[[Upstream fish migration]]]] | ||

=Introduction= | =Introduction= | ||

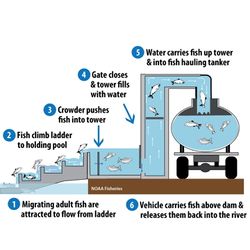

[[file:Truck Transport square.jpg|thumb|250px|Figure 1: Illustration of trap and haul truck transport of fish past a barrier.]] | [[file:Truck Transport square.jpg|thumb|250px|Figure 1: Illustration of trap and haul truck transport of fish past a barrier.]] | ||

| Line 20: | Line 21: | ||

=Classification table= | =Classification table= | ||

{{Template: Truck transport}} | {{Template: Truck transport}} | ||

| − | [[category:Upstream fish migration measures]][[category: | + | |

| + | =Relevant literature= | ||

| + | |||

| + | [[category:Upstream fish migration measures]][[category:Solutions]] | ||

Latest revision as of 10:03, 26 October 2020

Contents

Introduction

In the case of high head migration barriers, and especially where there are a series of barriers after each other, catch and transportation of fish on tank lorries has been used. The method can be used for up and down migration and has been used for eel, glass eel and salmon smolt. In Norway, this has been used to release adult salmon and sea trout above artificial and natural barriers, to ensure or increase fish production. The method relies on good catch efficiency and requires relatively large effort. It is basically very selective and requires repetitions in the long term but can still contribute to the occurrence or fish production of a species when other durable solutions are not realizable. Capture and transport can also be used as a temporary solution until a lasting solution is in place. The solution is used in special cases and is not recommended as a best practice.

Methods, tools, and devices

During planning

Planning of truck transport of fish must discover the relevant road system and parking places for loading and emptying the tank truck. In particular, a system for collecting fish and filling the truck must be planned, including a lifting or pumping system. A counting system for fish should be considered

During implementation

The implementation requires road and construction works and mechanical installations for a filling and counting station system downstream or next to a powerplant and a parking place for emptying the truck.

During operation

The maintenance is connected to the truck itself and any other pumping or monitoring systems.

Relevant MTDs and test cases

| Relevant MTDs | |

|---|---|

| 3D fish tracking system | |

| 3D sensorless, ultrasound fish tracking | |

| Barotrauma detection system | |

| Radio frequency identification with passive integrated transponder (PIT tagging) | |

| Visible implant elastomer | |

| Relevant test cases | Applied in test case? |

| N/A | - |

Classification table

| Classification | Selection |

|---|---|

| Fish species for the measure | All |

| Does the measure require loss of power production | - |

| - | |

| Structural (requires no additional flow release) | |

| Recurrence of maintenance | Irregular at events |

| Which life-stage of fish is measure aimed at | - |

| - | |

| - | |

| Movements of migration of fish | |

| Which physical parameter is addressed | N/A |

| - | |

| - | |

| - | |

| - | |

| - | |

| - | |

| - | |

| Hydropower type the measure is suitable for | Plant in dam |

| Plant with bypass section | |

| Dam height (m) the measure is suitable for | All |

| Section in the regulated system measure is designed for | In dam/power plant |

| Upstream of hydropower plant | |

| Bypass section | |

| Downstream outlet | |

| River type implemented | Steep gradient (up to 0.4 %) |

| Fairly steep with rocks, boulders (from 0.4 to 0.05 %) | |

| Slow flowing, lowland, sandy (less than 0.05 %) | |

| Level of certainty in effect | Moderately certain |

| Technology readiness level | TRL 8: system complete and qualified |

| Cost of solution | See cost table |