Difference between revisions of "OpenFOAM"

Bendikhansen (talk | contribs) |

Bendikhansen (talk | contribs) |

||

| (15 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | [[file:openfoam_logo.png|right]] | + | [[file:openfoam_logo.png|right|250px]] |

=Quick summary= | =Quick summary= | ||

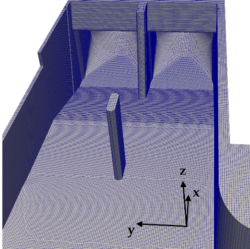

[[file:openfoam_grid.png|thumb|250px|Figure 1: Example of turbine inlet (flow in x-direction) modelled using an unstructured computational grid for OpenFOAM simulations (source: VAW).]] | [[file:openfoam_grid.png|thumb|250px|Figure 1: Example of turbine inlet (flow in x-direction) modelled using an unstructured computational grid for OpenFOAM simulations (source: VAW).]] | ||

[[file:openfoam_structure.png|thumb|250px|Figure 2: Case directory structure in OpenFOAM (source: CFD Direct ® OpenFOAM)]] | [[file:openfoam_structure.png|thumb|250px|Figure 2: Case directory structure in OpenFOAM (source: CFD Direct ® OpenFOAM)]] | ||

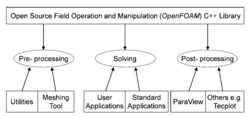

[[file:openfoam_structure2.png|thumb|250px|Figure 3: Overview of OpenFOAM structure (source: CFD Direct ® OpenFOAM).]] | [[file:openfoam_structure2.png|thumb|250px|Figure 3: Overview of OpenFOAM structure (source: CFD Direct ® OpenFOAM).]] | ||

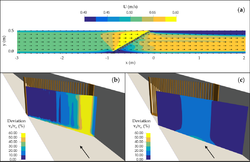

| − | [[file:openfoam_paraview.png|thumb|250px|Figure | + | [[file:openfoam_paraview.png|thumb|250px|Figure 4: Example of ParaView visualization of OpenFOAM simulation results showing horizontal flow velocities in a rectangular channel with a curved bar rack (CBR) for horizontal plane at 0.2 m (a). Deviation (in percent) of the ratio between tangential vt and normal velocities vn for the MCR compared to the situation without screen 5 cm (b) and 40 cm (c) upstream of the screen axis. The black arrows represent the flow direction (source: VAW).]] |

Developed by: 2018 (OpenFOAM release v1812) | Developed by: 2018 (OpenFOAM release v1812) | ||

| Line 11: | Line 11: | ||

Type: [[:Category:Tools|Tool]] | Type: [[:Category:Tools|Tool]] | ||

| − | |||

| − | |||

=Introduction= | =Introduction= | ||

| − | OpenFOAM is a C++ toolbox for simulation of general continuum mechanics problems including the Navier-Stokes equations that mathematically describe the 3D motion of fluids. For simulations of free-surface gravity flows, the prebuilt Eulerian’ solver interFOAM is most suitable. The interFOAM solver identifies the interface between water and air based on the Volume | + | OpenFOAM is a C++ toolbox for simulation of general continuum mechanics problems including the Navier-Stokes equations that mathematically describe the 3D motion of fluids. For simulations of free-surface gravity flows, the prebuilt Eulerian’ solver interFOAM is most suitable. The interFOAM solver identifies the interface between water and air based on the Volume of Fluid (VOF) method and uses the PIMPLE algorithm for pressure-velocity coupling. The governing flow equations can be solved in combination with different approaches for turbulence modelling. In OpenFOAM, Reynolds-averaged Navier-Stokes (RANS) models using one or two equation turbulence models (e.g. k-ε model) as well as more computationally expensive large eddy simulation (LES) methods are available. An advantage of OpenFOAM, besides its free availability, is the use of body-fitted or unstructured computational grids. The additional use of polyhedral cells (in addition to hexahedral cells) allows even complex geometries to be accurately mapped (Figure 1). |

=Application= | =Application= | ||

| − | The operating system for OpenFOAM is Linux and there is no official Graphical User Interface (GUI). The basic directory structure for an OpenFOAM case containing the minimum set of files required to run an application is shown in Figure | + | The operating system for OpenFOAM is Linux and there is no official Graphical User Interface (GUI). The basic directory structure for an OpenFOAM case containing the minimum set of files required to run an application is shown in Figure 2. All the files can be accessed with a text editor. In the system directory, the parameters associated with the solution procedure itself are defined (e.g. start/end time, solution schemes). The constant directory contains the description of the mesh and files specifying the physical properties. The time directories contain data files that can be either initial values, boundary conditions or results written to file. |

| + | |||

| + | OpenFOAM is supplied with a pre- and post-processing environment. The interface to the pre- and post-processing are OpenFOAM utilities, thereby ensuring consistent data handling across all environments. The overall structure of OpenFOAM is shown in Figure 3. | ||

| + | In the pre-processing, simple meshes containing blocks of hexahedral cells can be generated by the blockMesh utility. For more complex geometries, the snappyHexMesh utility automatically generates meshes containing split-hexahedral cells by iteratively refining the starting mesh and morphing the resulting split-hex mesh to the triangulated surface of solid geometrical structures like power plant facilities (Figure 2). Solid structures are represented in the form of stereolithographic files (STL). | ||

| + | The main post-processing tool provided with OpenFOAM is the reader module paraFoam that uses ParaView, an open-source visualization software to display geometry, computational mesh and simulation results (Figure 4). | ||

| − | + | =Relevant mitigation measures and test cases= | |

| − | + | {{Suitable measures for OpenFOAM}} | |

| − | |||

=Other information= | =Other information= | ||

Latest revision as of 09:29, 18 September 2020

Contents

Quick summary

Developed by: 2018 (OpenFOAM release v1812)

Date: May 2018 (Version 2.8)

Type: Tool

Introduction

OpenFOAM is a C++ toolbox for simulation of general continuum mechanics problems including the Navier-Stokes equations that mathematically describe the 3D motion of fluids. For simulations of free-surface gravity flows, the prebuilt Eulerian’ solver interFOAM is most suitable. The interFOAM solver identifies the interface between water and air based on the Volume of Fluid (VOF) method and uses the PIMPLE algorithm for pressure-velocity coupling. The governing flow equations can be solved in combination with different approaches for turbulence modelling. In OpenFOAM, Reynolds-averaged Navier-Stokes (RANS) models using one or two equation turbulence models (e.g. k-ε model) as well as more computationally expensive large eddy simulation (LES) methods are available. An advantage of OpenFOAM, besides its free availability, is the use of body-fitted or unstructured computational grids. The additional use of polyhedral cells (in addition to hexahedral cells) allows even complex geometries to be accurately mapped (Figure 1).

Application

The operating system for OpenFOAM is Linux and there is no official Graphical User Interface (GUI). The basic directory structure for an OpenFOAM case containing the minimum set of files required to run an application is shown in Figure 2. All the files can be accessed with a text editor. In the system directory, the parameters associated with the solution procedure itself are defined (e.g. start/end time, solution schemes). The constant directory contains the description of the mesh and files specifying the physical properties. The time directories contain data files that can be either initial values, boundary conditions or results written to file.

OpenFOAM is supplied with a pre- and post-processing environment. The interface to the pre- and post-processing are OpenFOAM utilities, thereby ensuring consistent data handling across all environments. The overall structure of OpenFOAM is shown in Figure 3. In the pre-processing, simple meshes containing blocks of hexahedral cells can be generated by the blockMesh utility. For more complex geometries, the snappyHexMesh utility automatically generates meshes containing split-hexahedral cells by iteratively refining the starting mesh and morphing the resulting split-hex mesh to the triangulated surface of solid geometrical structures like power plant facilities (Figure 2). Solid structures are represented in the form of stereolithographic files (STL). The main post-processing tool provided with OpenFOAM is the reader module paraFoam that uses ParaView, an open-source visualization software to display geometry, computational mesh and simulation results (Figure 4).

Relevant mitigation measures and test cases

Other information

General advantages & disadvantages of the tool (no claim for completeness)

|

Pros |

Cons |

|

Open source software |

Complex model setup (no GUI) |

|

Accurate representation of complex geometries due to unstructured or body-fitted computational grids |

Definition of boundary and initial condition requires in depth knowledge of underlying concepts |

|

Growing user community (forum) |

No standardized documentation |

Relevant literature

- Feigenwinter, L., Vetsch, D., Kammerer, S., Kriewitz, R.C., Boes, R.M. (2018) Conceptual Approach for Positioning of Fish Guidance Screens Using CFD and expert knowledge. Sustainability, under review.Fuentes-Perez, J.F., Silva, A.T., Tuhtan, J.A., Garcia-Vega, A., Carbonell-Baeza, R., Musall, M., Kruusmaa, M. (2018). 3D modelling of non-uniform and turbulent flow in vertical slot fishways. Environmental Modelling and Software, 99, 156-169, doi:10.1016/j.envsoft.2017.09.011.

- Gisen, D.C., Weichert, R.B,; Nestler, J.M. (2017) Optimizing attraction flow for upstream fish passage at a hydropower dam employing 3D Detached-Eddy Simulation. Ecological Engineering, 100, 344-353, doi:10.1016/j.ecoleng.2016.10.065.

- Raynal, S., Chatellier, L., David, L., Courret, D., Larinier, M. (2013). Numerical Simulations of Fish-Friendly Angled Trashracks at Model and Real Scale. Proceedings of the 35th Iahr World Congress, Vols I and II, 2557-2566.

Contact information

OpenFOAM download: https://www.openfoam.com / https://openfoam.org

User guide and tutorials: https://www.openfoam.com/documentation

Paraview: https://www.paraview.org